The Jesko’s transmission alone could fill the whole 20-minute video.

There are few things in life that bring me as much joy as technical deep-dive videos in which you get to see the intricate details of not only some of the most fascinating cars on the planet, but also how they’re made. It doesn’t matter if it’s old-school hand-craftsmanship like Morgan, obsessive attention to detail like Gordon Murray, or absolute mind-bending, cutting-edge engineering like Koenigsegg: I love it all. This video features the latter, with Christian von Koenigsegg himself talking you through some of the most fascinatingly nerdy engineering behind the Jesko.

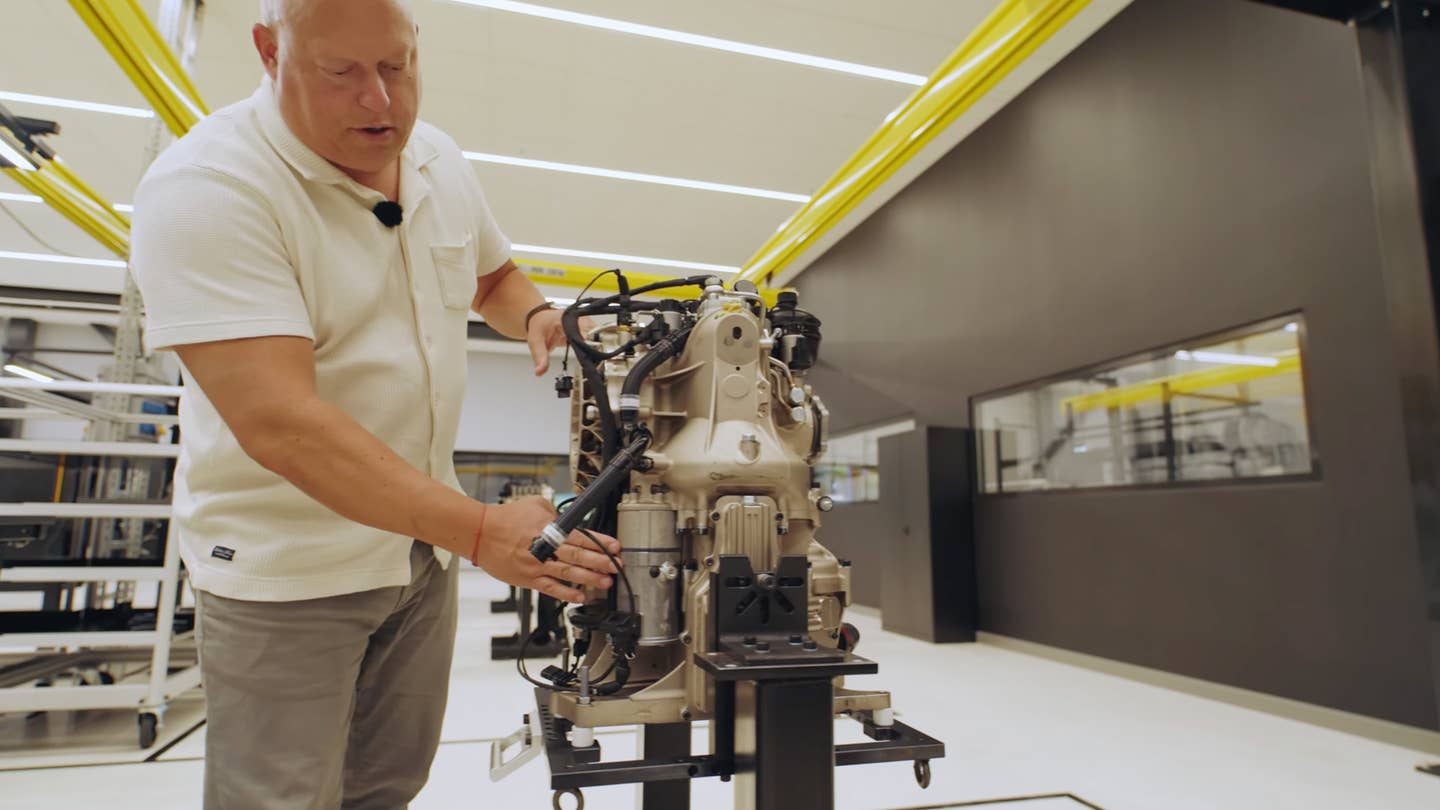

Stepping into the Jesko’s assembly facility looks more like you’re walking into an operating room rather than an automotive assembly plant. It’s spotless, clinical, and quiet, which is something only a brand like Koenigsegg has the ability to be. As a super-low-volume hypercar maker, Koenigsegg can take its time, letting its engineers assemble its complex components slowly and carefully. Each Jesko transmission takes a single person an entire week to assemble. A whole week for one transmission!

Koenigsegg

When Koenigsegg first announced the Jesko, its transmission was one of its most interesting parts. The company dubbed it the “Light Speed Transmission,” and it features nine gears and seven clutches. You can see all of the components laid out on a table in the video, and each one looks like it costs more than my house. They’re almost certainly made better, too. Koenigsegg explains how the clutches work, how it allows the engine to ditch its flywheel, and how its low inertia helps the engine rev so quickly.

The Jesko’s engine—a 5.0-liter twin-turbocharged V8—makes 1,280 horsepower on pump gas but that jumps up to 1,600 horsepower with E85. But its power is probably the least interesting thing about it. Every hypercar company has 1,000 horsepower-plus engines right now. What makes the Koenigsegg engine so interesting is how well it revs and sounds despite being twin-turbocharged. One of the reasons it sounds so good is its titanium and Inconel exhaust. The gorgeous looking headers are actually made from 3D-printed Inconel, which is the first time I’ve ever heard of a brand 3D-printing Inconel. You can see and, critically, hear a dyno test of the engine in the video. It sounds killer.

Koenigsegg

This video isn’t quite as nerdy as some of those that came from Gordon Murray, surrounding the launch of both his T.50 and T.33, but it’s still great to watch. For those of you like me, who love to get into the nitty-gritty of the most fascinatingly built cars in the world while also getting short engineering lessons, this video is a must-watch.

Got tips? Send ’em to tips@thedrive.com