The Tesla Cybertruck is equipped with an all-new 48-volt low-voltage system, which replaces the outdated but still the popular, 12-volt system.

This move from 12- to 48 volts for auxiliary onboard devices was confirmed by Tesla during the 2023 Investor Day in March and applied in the final product as promised.

*The main traction battery system that runs the drive units is a high-voltage one with a nominal voltage of over 800 volts.

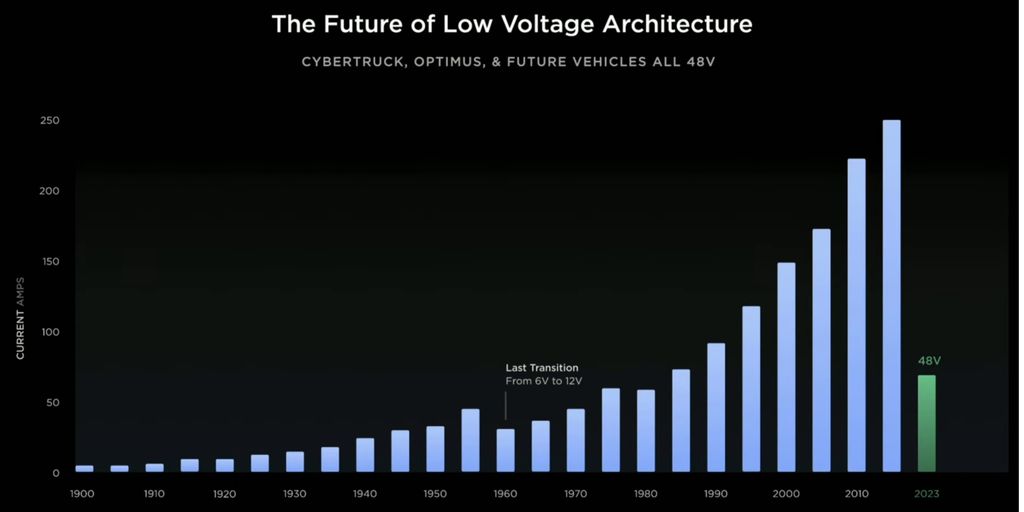

The main benefit of higher voltage for auxiliary devices is that the same power can be supplied at a lower current, which directly lowers the current losses and allows the use of thinner wires to save weight and cost. Large vehicles already were using 24-volt systems, but 48-volt is still a rare solution in cars.

Tesla does not intend to stop there by simply moving from 12 volts to 48 volts for its own electric vehicles. The automaker would like to help spread the 48-volt architecture through the industry.

This is why Tesla sent the 48-volt system specs to other manufacturers and Ford CEO Jim Farley just confirmed that he received it.

Considering his response “Great for the industry!” we can assume that Ford will be willing to implement a 48-volt system in its vehicles as well, potentially starting with some next-generation all-electric vehicles.

Tesla CEO Elon Musk also responded, “You’re welcome.” Perhaps we’ll soon see some other manufacturers hint at 48 volts now.

Update: In a following post, Jim Farley said: “Great to read the document and realize that our next-gen team has been on a similar path. Let’s work together to help the supply base move into the 48V future as well.” This clearly indicates that the next-generation Ford all-electric vehicles will also have a 48-volt system.

Despite many obvious benefits, the automotive industry is sometimes very slow to change the things that work for something better.

The switch from 12 volts to 48 volts is not as simple as one would think, because it requires redesigning vehicle wiring and (at least in most cases) all new electric components (every motor, light, sensor, and chip) or at least ensuring that they can operate at a higher voltage.

The issues are that this requires investment, there are not that many suppliers of parts and there is no economy of scale at the beginning. The changes also mean that all of the service centers need to be ready for the new low-voltage system.

With Tesla’s template of a 48-volt low-voltage system, the rest of the industry might be willing to develop their own solution—first, because it will be easier to start from something rather than from scratch, and secondly, because now the competition is one step ahead.

Following the first Tesla Cybertruck deliveries, Munro Live‘s Sandy Munro had an opportunity to speak with Elon Musk about the 48-volt system and issues that prevented such a move in the past.

Let’s also recall that in new electric cars, Tesla still uses a 12-volt low-voltage system, but already managed to switch from the typical lead-acid auxiliary batteries to 12-volt lithium-ion auxiliary batteries. The switch was announced in February 2021, and initially launched in the refreshed Tesla Model S/Model X (starting with the Plaid) – see an in-depth teardown here – and later used also in the Model 3/Model Y (in late 2021).

We haven’t seen the Tesla Cybertruck’s auxiliary battery yet, and an online manual has not yet been released but we assume that the new 48-volt battery in the Tesla Cybertruck is also a lithium-ion battery. The question is what type of battery cells (and from whom) were used?