Redwood Materials, the battery recycling effort started by Tesla alum JB Straubel, sees its mission as critical for ramping up domestic content in American EVs—as well as for helping automakers meet sustainability targets.

Last month, Redwood detailed one way it’s actually making that process happen on the ground: It’s started an online portal for end-of-life EV batteries. Through it, U.S. automotive dismantlers—also known as salvage yards—can enter details regarding what they have and get an instant offer for their battery pack.

Automotive recycling isn’t as centralized as you might think, but through a tangle of connections and partnerships for various components, most of the materials in old vehicles find a new use. In the U.S. there are more than 9,000 automotive recycling locations, employing 140,000. Redwood says cars are the most recycled item in the U.S., with around 12 million vehicles recycled per year.

According to the Automotive Recyclers Association, about 86% of vehicle material content is recycled, reused, or used for “energy recovery,” and from the combined efforts of recyclers about 8 million gallons of gas and diesel, 24 million gallons of motor oil, and 96% of lead-acid batteries are collected for reuse or recycling.

At the same time, this is when the number of EVs reaching recyclers is accelerating, and it’s an important step in establishing the U.S. battery-material ecosystem.

Toyota and Redwood Materials battery recycling

Yes, the afterlife for your Leaf or Prius battery

Just in 2024, Redwood expects 250,000 electrified vehicles to reach end-of-life. That includes a whole lot of hybrids. Toyota, for instance, earlier this month confirmed plans to source recycled material for Toyota EV batteries from Redwood, with the hope of recovering materials from earlier retired Prius hybrids.

Several other automakers have made deals with Redwood. VW and Audi EV batteries will be retired through the firm, and shipped to Nevada for recycling, and a Ford partnership seeks a “closed loop” circular EV supply chain with Redwood. The firm will plan an “outsized role in bringing the battery supply chain home,” according to Energy Secretary Jennifer Granholm, and it’s receiving a $2 billion DOE loan for expansion.

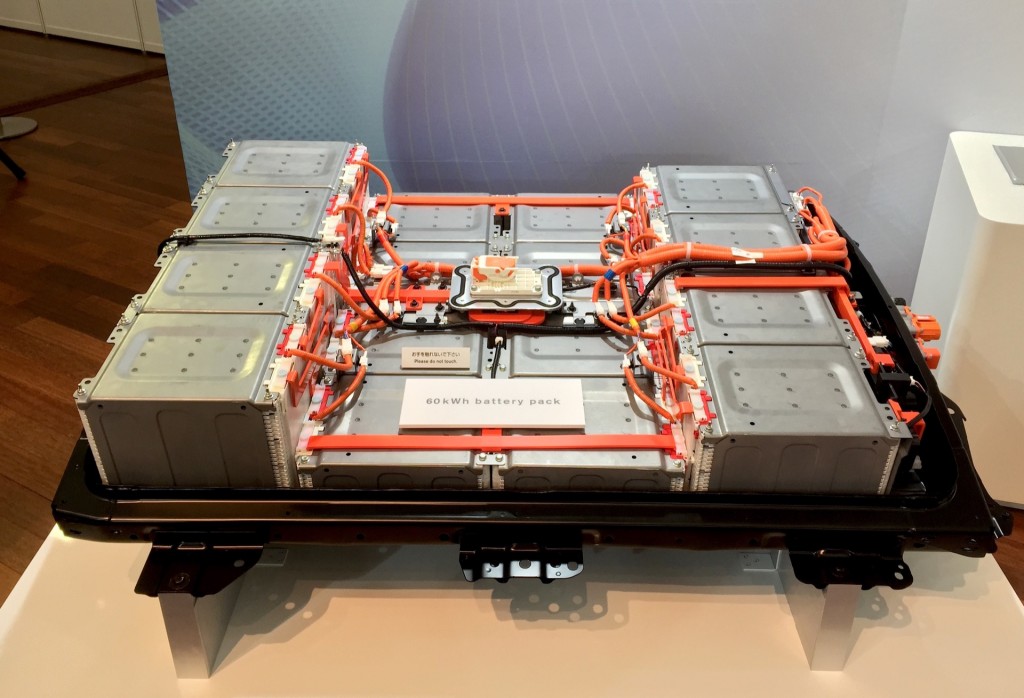

Nissan prototype 60-kWh battery pack – Nissan Technical Center, October 2015

Redwood launched a California pilot program in early 2022, and after the first 12 months of the program it reported 1,268 battery packs collected from 19 different EV and hybrid models, 82% of which included lithium-ion cells. It claims that it was able to recover more than 95% of lithium, cobalt, nickel, copper, and other materials from the packs.

As part of that program, Redwood is already working with automotive dismantlers.

Toyota and Redwood Materials battery recycling

No parallels to the catalytic converter epidemic

Given the large number of recyclers, and rampant issues with catalytic converter theft, are there any such concerns for EVs? Redwood told GCR that it specifically approves each transaction, with vehicle title and serial numbers verified, and that it has a team ready to help dismantlers with questions or concerns in processing EV battery packs.

An EV battery pack is by no means a catalytic converter either, and it requires time and skill to remove. Through its portal, once Redwood accepts the sale, it handles transportation of the pack, which can often be 1,000 pounds or more.

“Everyone we worked with in the dismantler community wants to do the right thing and they were excited to partner directly with Redwood to ensure responsible recycling,” reported Redwood of its California program, noting that the dismantler community helped it find the most efficient way to handle, package, and ship heavy EV packs.

Now, it’s time to scale up.