From the November 2023 issue of Car and Driver.

Painted like a bull’s-eye in the back corner of Toyota‘s factory in Motomachi, Japan, is a large turntable redirecting freshly minted GR Corollas (and foreign-market-only GR Yarises) onto an alignment rack, obviating the need to turn their steering wheels. It’s a seemingly simple procedure imposed by the assembly line’s compact layout. The aim is to minimize uneven loads on the new cars’ suspension bushings, thereby improving the precision of final chassis adjustments—uncanny attention to detail for a major manufacturer to impart on what are essentially hopped-up economy cars. But as racing-inspired driver’s cars, these limited-production hot hatchbacks have posed unprecedented challenges to Toyota’s traditional manufacturing methods.

Propelled into being for the 2023 model year by former CEO and all-around car guy Akio Toyoda, the GR Corolla is the handiwork of Toyota’s performance and motorsports division, Gazoo Racing. With all-wheel drive, a 300-hp turbo inline-three, and a close-ratio six-speed manual, this effervescent sport compact materialized as a larger, North American–focused compatriot of the GR Yaris, which forms the basis for Gazoo’s top-tier World Rally Championship (WRC) race car. The four-door GR Corolla’s exuberance at a $36,995 starting price quickly earned it a 10Best award, plus a place among Toyota’s best home-grown performance machines next to the two-door GR Yaris. Perhaps fittingly, both cars are produced at the same facility that previously built the $350,000 Lexus LFA. (Assembly of Toyota’s GR86 and GR Supra models falls to their respective development partners, Subaru and BMW.)

Compared with Motomachi’s other assembly lines that churn out boatloads of mainstream models, the separate Gazoo Racing factory’s daily output—a mere 49 GR Corollas, eight GR Yarises, and four track-focused GRMN Yaris models—amounts to a rounding error. A high level of specialization is essential to the low-volume operation, with GR workstations arranged in semipermanent cells that combine several of the regular Corolla’s production steps into one. Using electric power tools rather than compressed air to lift and locate heavier subassemblies reduces costs and complexity by eliminating the need to run fixed air lines. Similarly, in place of bulky conveyor systems, autonomous tugs running along the floor help shuttle partial vehicles from station to station. Workers check the machines’ output by hand and push body shells around on dollies.

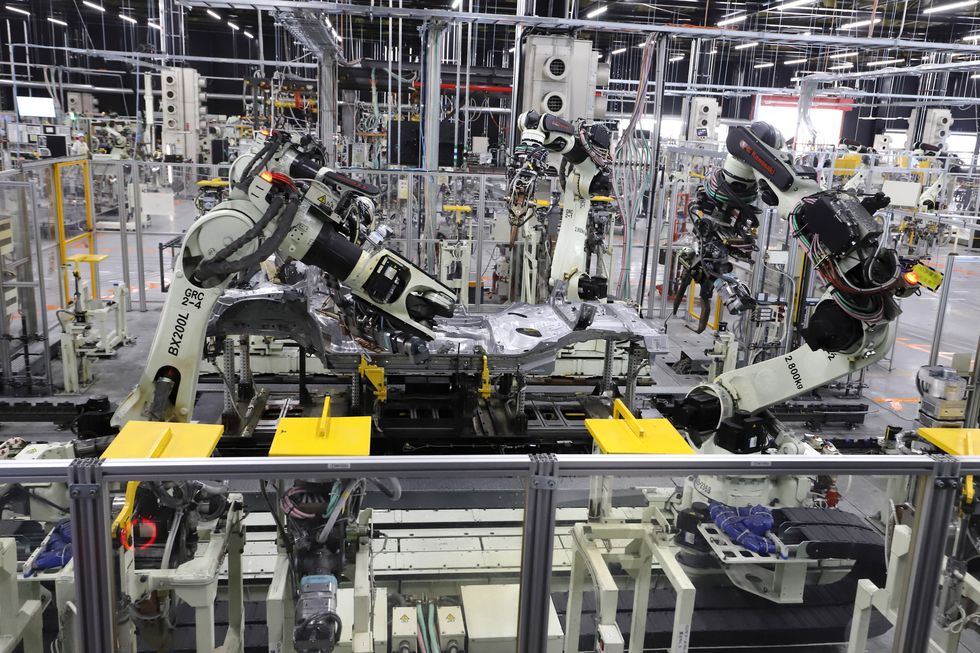

The GR Corolla’s solid feel and crisp reflexes largely stem from a structure reinforced with nine extra feet of adhesive and 349 additional spot welds compared with its mass-produced siblings. And whereas volume versions get welded together on an eight-stage daisy chain of fixtures, the GR’s body shell takes shape on a single jig, greatly tightening its tolerances. The mounting points for each car’s suspension are scanned and measured, and the data is used to match up individual components with complementary variances. Any similarities to how Gazoo constructs its race cars are not coincidental, as Toyoda, now chairman, helped instill learnings from motorsports in both the development and the assembly of its production vehicles. His guiding message: Make GR models fit for the racetrack right off the showroom floor.

That ethos undergirded the creation of the two GR-branded hatchbacks. No stranger to competition, Toyoda (known as Morizo when racing, hence the GR Corolla’s hardcore Morizo edition) pushed engineers to function as a race team, over coming challenges as a unit and accelerating the development process. From the start, it was crucial to measure progress not only with lap timers and data recorders but also by the smiles on drivers’ faces when they were behind the wheel. “Fast is important, but the driver must also enjoy,” says GR Corolla chief engineer Naoyuki Sakamoto. “An enjoyable car is a car that the driver can trust, gives the feed-back you need, and responds exactly how you intend. That is the formula for a fun car.”

As body shells trundle off to be painted, workers are busy organizing racks of chassis components. Coil springs are measured and matched by minute rate differences for the best side-to-side balance. For each of the cars’ four-piston front and two-piston rear brake calipers, compressed air is used to measure their volumetric efficiency, again pairing them up for optimal balance. They are assembled into larger corner units, with a separate jig helping overlay the mounting-point measurements of the various components with the body data of the cars coming down the line. The results are more precise alignment of bolt holes and tiny wheel-angle variances compared with regular Toyota models.

Along with the work done in Motomachi, GR Corolla drivers owe much of their enjoyment to Toyota’s proving ground outside Nagoya [see “Japan’s Little Midori Hell,” below]. With its daunting handling course, the facility helped the GR team hone their creation to generate the big smiles needed to satisfy enthusiasts. This refinement process led to pushing back development of the car by a year to massage its chassis further and squeeze more power out of its turbocharged 1.6-liter three-cylinder [see “Rallying Cries,” below]. Combining the GR cars’ working bits with their painted bodies is the most comprehensive production step and the only point where the assembly line branches into multiple paths. Unlike how regular models come together, with their chassis components married to body shells suspended from overhead, GR models take shape just as fire-breathing WRC Yaris hybrids do: Bodies are lowered onto stationary underpinnings, which Toyota claims ultimately makes for a stronger connection by reducing stresses on the cars’ skeletons.

Will Toyota build future GR models in the same painstaking manner? “Of course,” says Gazoo Racing president Tomoya Takahashi. And there’s good reason to believe him, what with former GR boss Koji Sato having taken the reins as Toyota’s CEO. Meanwhile, development of the GR Corolla continues. “We’ve hidden some additional potential in the vehicles,” Takahashi says. His team is now analyzing feedback from racers, including those who competed in Japan’s Super Taikyu endurance series with an experimental GR Corolla powered by a liquid-hydrogen-burning three-cylinder engine. Gazoo also plans to support its cars throughout their life cycles by offering a range of aftermarket performance parts. While Takahashi says electric models will likely join the GR lineup at some point, they will be challenging to develop because their driving characteristics are more difficult to “flavor.”

Why Gazoo? Toyota united its motorsports activities under Gazoo Racing in 2015. The word “Gazoo” originally derives from “gazō” (the Japanese word for “image”), which in the 1990s formed the nexus for a photo-centric Toyota used-car website, gazoo.com. Today the term has evolved within the company to mean “garage,” as in a place where engineers sweat a car’s details.

Back at Motomachi, assembled cars undergo an exhaustive array of motorsports-inspired verification steps. On the alignment rack, testers add weighted bags simulating two passengers and a tank of fuel (165 pounds on each front seat, 55 pounds in the cargo area) for ballast. Achieving the most accurate steering feel requires setting and then checking and resetting the rear-axle alignment before making any tweaks to the front end. The GR Corolla’s masterfully tuned brake pedal is verified for pressure and progression, followed by another round of chassis and suspension measurements. If any figures fall out of tolerance, new components and different wheels and tires are fitted, and the entire finishing process is started anew. Only once a car gets the green light from here is it taken for a test drive and prepped for shipping.

Speak to anyone at Gazoo Racing about the GR Corolla’s essence as a driver’s car, and their eyes fill with passion. For many, it represents a dream car they could one day own. “I developed what I want to have,” Sakamoto says, though he admits he’s still patiently waiting in line to take delivery. That sense of pride extends to the teachings the Gazoo team has shared with Toyota as a whole, even if some feathers within the company’s greater bureaucracy got ruffled in the process. “There’s sort of an unspoken rule not to break cars during development,” says Takahashi. “But with Akio, he thanks you if you break the cars. This really changed the perspective of the engineers. A reward for pushing the limits is now possible, and the GR Corolla and Yaris are the result of that kind of carbuilding.”

Rallying Cries

While Toyota’s World Rally Championship–spec Yaris race car features a hybridized turbo four-cylinder, the production GR Corolla and GR Yaris are powered by a turbo three that produces 300 horsepower and 295 pound-feet of torque in the Corolla’s top Morizo tune. Assembled on a separate production line near the company’s Shimoyama testing complex, this G16E-GTS engine receives performance-focused attention, including the matching of its cast-aluminum pistons by weight. Toyota says it chose the 1.6-liter three-cylinder for the configuration’s more favorable torque curve and reduced exhaust back pressure compared with an inline-four. Displacement is 1618 cubic centimeters for eligibility in the WRC2 (Rally2) class, an affordable support series in which the GR Corolla was originally designed to compete. A prototype of Toyota’s Rally2-spec customer race car, which the company hinted at with a concept shown at SEMA last year, will tackle its first stages this year.

Japan’s Little Midori Hell

The Toyota Technical Center Shimoyama, located in the lush mountains near the company’s Toyota City headquarters, began partial operations in 2019 and played a significant role in the development of the GR Corolla. Built at a cost of more than $2 billion, the 1608-acre site encompasses various test tracks. The headliner is its country-road handling course, a 3.3-mile roller coaster of a track inspired by Germany’s famed Nürburgring Nordschleife. Split into two lanes and incorporating pavement undulations for ride-quality testing, the course climbs, falls, and bends across 246 feet of elevation change and around some 32 corners. With blind switchbacks, sharp rises that can launch cars into the air, and fast, diving sweepers, it’s a challenging playground for chassis engineers. Towering catch fences keep vehicles on track in the event of an accident, for both driver safety and protection of the surrounding landscape, much of which remains untouched for environmental conservation.

Technical Editor

Mike Sutton is an editor, writer, test driver, and general car nerd who has contributed to Car and Driver‘s reverent and irreverent passion for the automobile since 2008. A native Michigander from suburban Detroit, he enjoys the outdoors and complaining about the weather, has an affection for off-road vehicles, and believes in federal protection for naturally aspirated engines.