PWC also disclosed the main culprits behind production delays, and a grand total of zero people will be surprised at what they are. We have the infamous supply chain issues (not just semiconductor chips, but several other bits and pieces), meeting the standards of quality demanded by the public, and workforce constraints, leading to problems in scaling up production. Electric vehicle components were explicitly named as a big issue.

The delays due to “other” factors include portfolio changes. Traditionally, changing a production line from one model to the next is an easy process that manufacturers are well versed in. But the switch over to electric cars brings all sorts of new issues, as we saw with the Ford F-150 Lightning. It’s based on the same platform as an ICE F-150; still, there were delays.

Another issue was launch timing. All cars scheduled to be launched in 2020 had to be moved back because factories were shut. Finally, we have changing customer preferences and expectations.

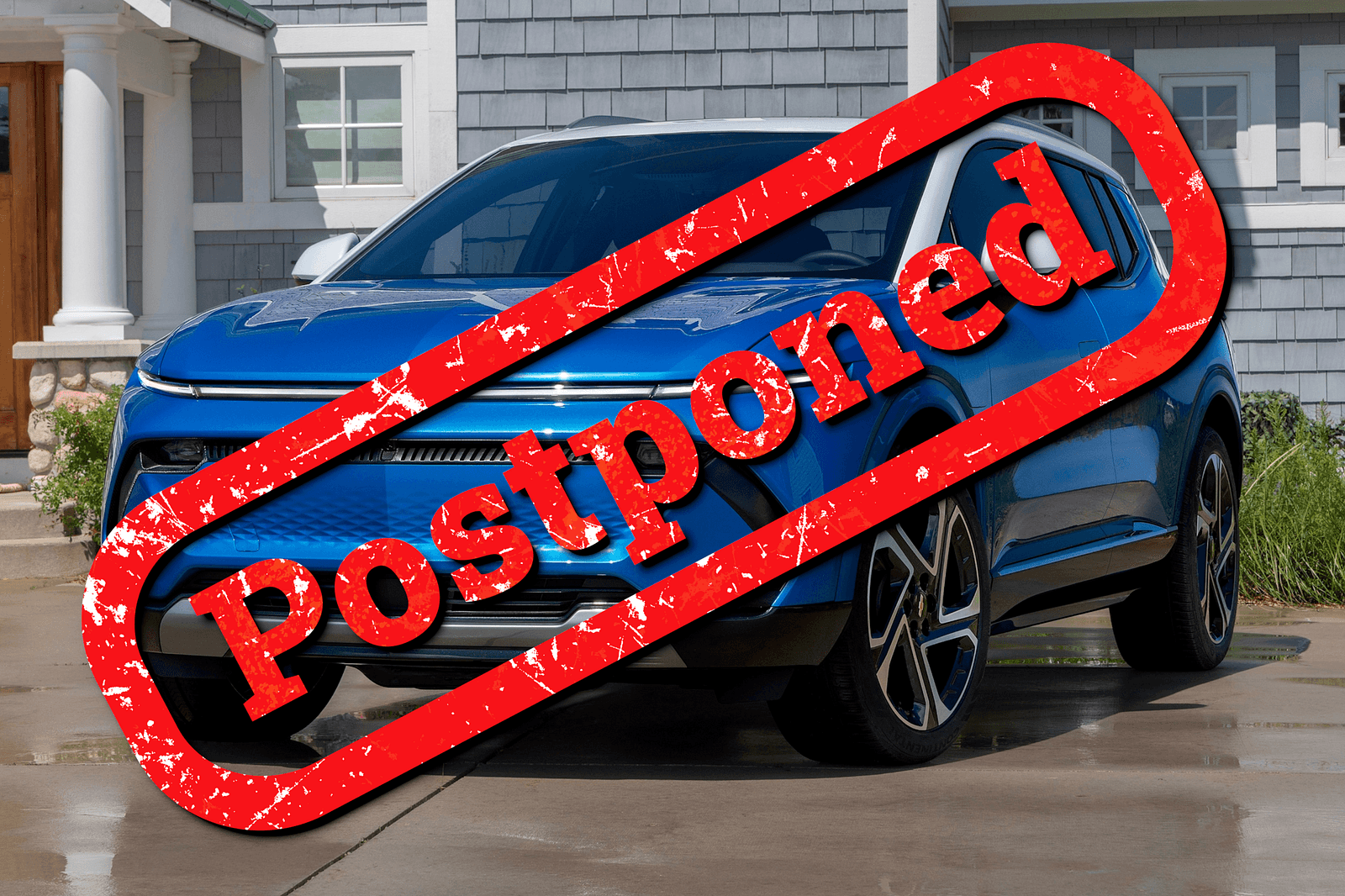

In monetary terms, a 12-month delay can cost a manufacturer up to $200 million. In 2023 alone, several cars were delayed for the reasons mentioned above.