There are a total of 64 stations that a car goes through to be completed; each station only takes nine minutes to complete its task. It takes a total of 127 minutes to complete a car.

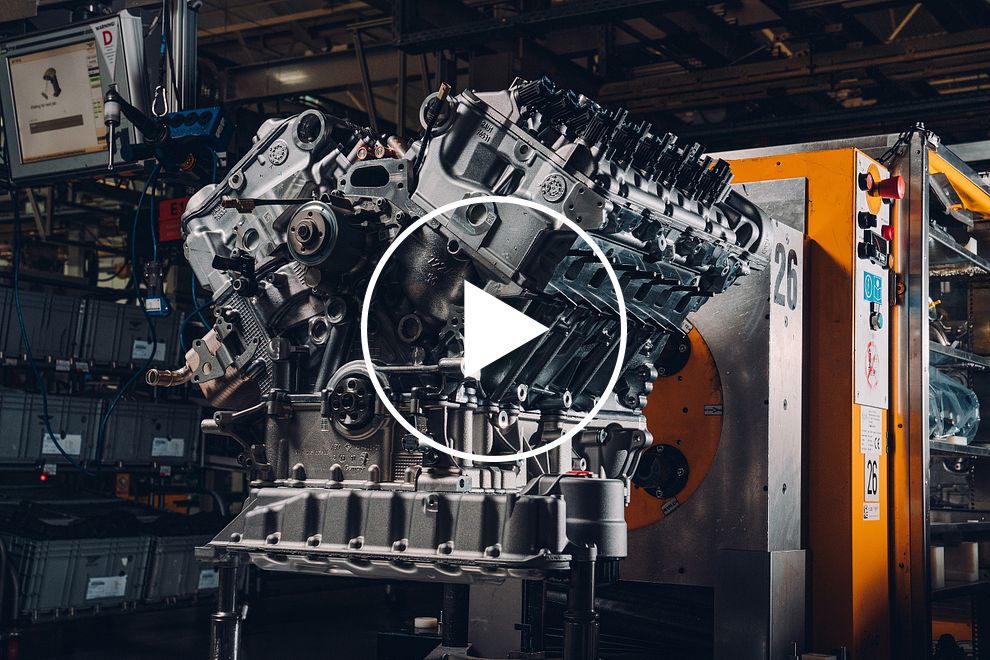

Once completed, these engines undergo rigorous pressure and dyno-testing, ensuring they match their specified outputs. While we’re sure they could achieve more, the highest output currently configured is the 740 horsepower and 738 lb-ft of torque attained for the Bentley Batur. Data analytics track the performance of each car and identify areas for improvement.

The historic Bentley factory in Crewe is the very first carbon-neutral automobile factory in the world, having received the internationally recognized PAS 2060 standard for carbon neutrality back in 2019.

The British marque aims to build on the carbon-neutral status of the Crewe factory by investing in the Bentley Dream Factory to become climate-neutral, end-to-end, from 2030 onwards.