Maybe Brian O’Conner wouldn’t have had any “danger to manifold” if he’d been running one of these.

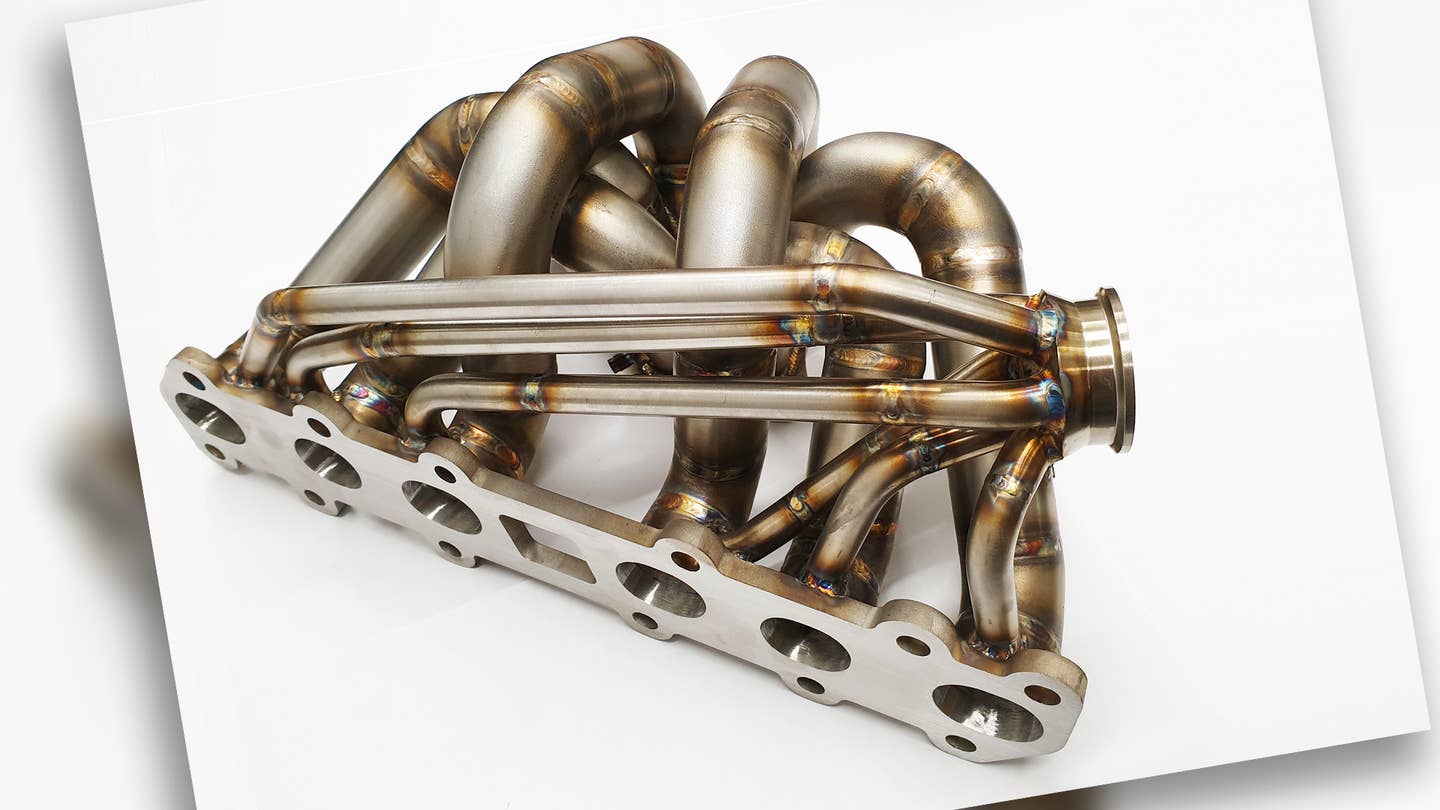

It’s common for top-of-the-line exhaust manifolds to look like Medusa, but the one you see here is more like Medusa with a parasite. What’s the deal? You might be wondering, along with how do I delete that EGR-lookin’ thing for more power? Well, you’ve got that backwards, because those pipes aren’t for emissions controls. They’re key to a little-known type of turbo anti-lag that’s probably coming to a tuning shop near you.

The manifold above was built British race shop Walton Motorsport, which says it has provided exhausts for rally cars, Le Mans, and even a championship-winning Formula 1 team. Suffice to say, this manifold has a secondary pipe coming off each exhaust runner for a reason. They look like they’d be for sending exhaust somewhere, perhaps through a second turbo or back through the engine for exhaust gas recirculation (EGR). But their role is the very opposite: Let in clean, un-combusted air.

Fresh-air anti-lag manifold with turbocharger and valving in place. Walton Motorsports

You’re looking at the workings of a form of anti-lag called fresh air (or bypass) anti-lag. Anti-lag is used to negate turbo lag by delaying ignition timing so combustion happens as the air-fuel mix leaves the cylinder, which keeps the turbo spooled with the throttle closed. This improves throttle response, which was historically a weakness of turbo engines.

Anti-lag is rarely seen outside top-level motorsport though, because it has big drawbacks. It can damage exhaust manifolds, turbochargers, and any emissions equipment downstream of them. Anti-lag also generates a small amount of horsepower while active, which can hurt drivability. It’s also incredibly loud, making it completely unsuitable for a road car. But fresh air anti-lag works slightly differently. The principle is the same; combustion still happens in the exhaust manifold, but much of the air gets there another way. And how it’s delivered has a big impact on the potency of the anti-lag itself.

Fresh air anti-lag diagram. Turbosmart via Walton Motorsports

With fresh air anti-lag, there’s a line directly from the charge pipe (downstream of the turbo intake) into the exhaust manifold. The connection is mediated by a one-way valve or two, which can also involve an accumulator tank that holds boost while the throttle’s closed. This way, the boost the turbo generates doesn’t have to go through the cylinder head, which Walton Motorsports’ blog says lets you feed more air directly into the turbo’s hot side. Apparently, the results speak for themselves.

In a YouTube video following a dynamometer trial, Walton said that with conventional anti-lag, he’s seen exhaust temperatures around 950 degrees. (Celsius or Fahrenheit aren’t specified, but the former is probable with a Brit.) With the fresh-air system, those temperatures dipped to 650 degrees, and the anti-lag is quicker and more effective to boot. On a demo car equipped with the 2JZ-GTE from a Toyota Supra, Walton says the system made 1.3 bar (19 psi) of boost at just 1,800 rpm while off the throttle.

Naturally, a turbine circuit such as this is liable to run away like a diesel if left unchecked. But Walton has safety measures in place, such as sensors for exhaust gas temperature and turbo speed. The only runaway this type of anti-lag will probably face is popularity, as Walton Motorsports says the parts that enable it have only become widely available to the public in the last few years after propagating in top-level rallycross. Not long from now, the tech could find its way to your local drag strip, drift circuit, or hill climb—if it hasn’t already.

Got a tip or question for the author? You can reach them here: james@thedrive.com