Toyota has been making dummy fingers out of pig skin for Science!

Toyota is most well-known for making reliable cars, but the Japanese auto giant puts an emphasis on the actual process of making cars and that involves squishy human workers who are prone to accidents on the factory floor—especially while working with heavy automated machinery. No matter how efficient the famous Toyota Production System is, it’s no good without human hands that pull the levers and push the buttons that keep the line running. But hands and fingers can easily be pinched or otherwise injured when working with robots, so Toyota took a handy approach and started making dummy fingers to evaluate and maximize the safety of its workers’ hands.

The fake fingers are made in Aichi Prefecture, Japan, at the company’s headquarters in Toyota City. Toyota says they’re made by a single employee, Takeo Mori, who’s a manager in the Manufacturing Engineering Department. Mori explains that the dummy fingers were developed with the help of Panasonic, and the point is to increase worker safety as robots take on a greater role in auto assembly. This is due, in part, to a lower birthrate in Japan that has led to a steady decline in the “working population,” per the Toyota Times.

Toyota

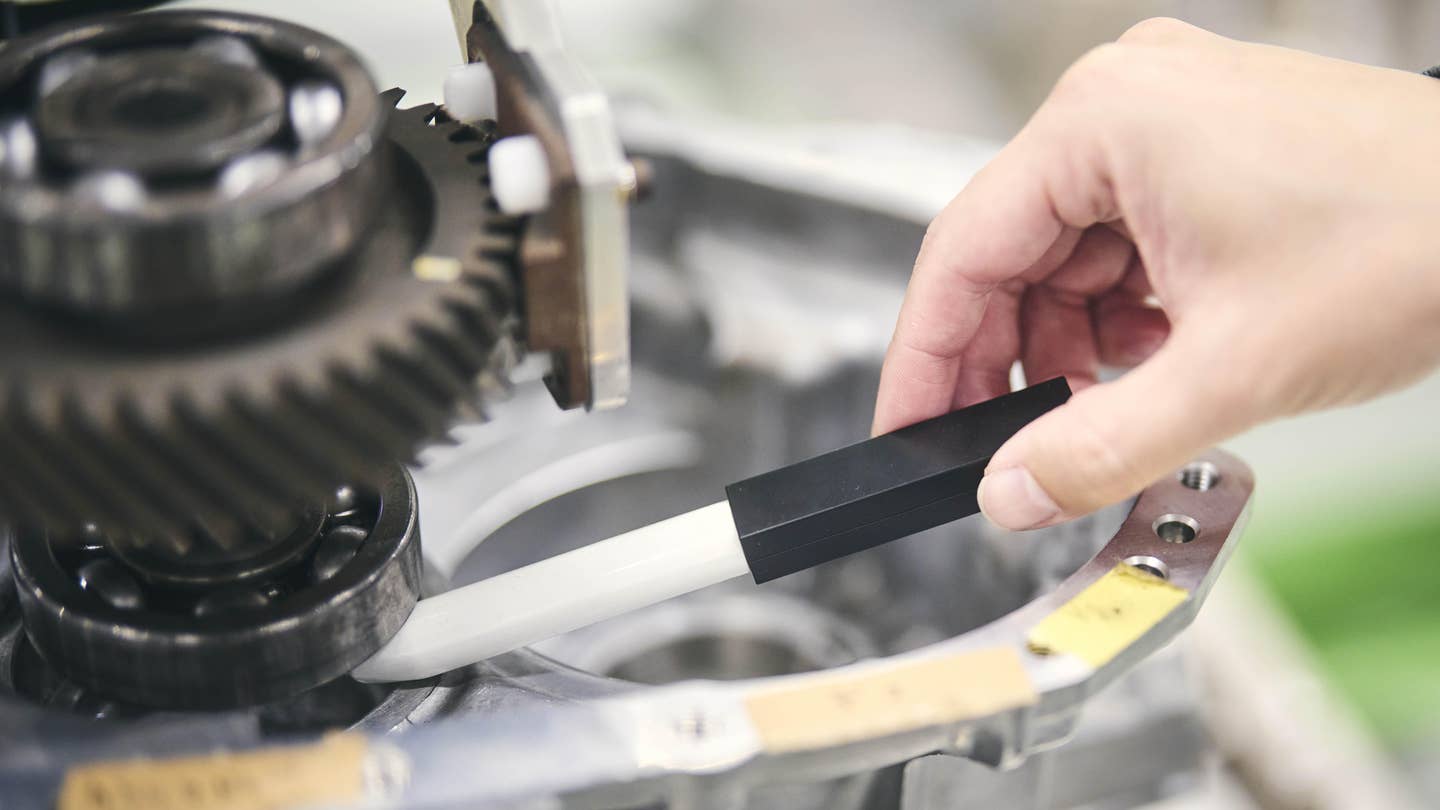

As people and robots work more closely together, the risk of workplace accidents goes up and the most common among these in the manufacturing industry are hand and finger injuries due to pinch hazards and the like; these can range from mild bruising to lacerations. Mori says that because “many automobile parts are hard or sharp,” Toyota “needed a tool that could assess the degree of finger entrapment in small surface areas.” Thus, the fake fingers were born.

Development of the dummy fingers began in 2018, and Toyota banded together with Panasonic and a research department at Nagoya University’s medical school, which were already working on similar projects. Panasonic was developing a product to analyze finger injuries, but that would have yielded a sophisticated device that relied on a computer to decipher the data. This kind of analysis takes time, and Toyota wanted to avoid delays in implementing the tool. So, it decided to go with something simple—what the carmaker calls an “analog system that would be easy to use on-site without a PC.” The idea was to make something that could visually convey how susceptible fingers were to injuries while working with machines,

The dummy digits allows engineers to adjust and tailor the forces that certain machines exert during the production process. Presumably, these are machines whose operations present frequent points of contact between people and robots.

The dummy finger has similar properties to a real finger, and is made using pig skin because it mimics the elasticity and feel of human skin. It even has a stainless steel core that simulates a human bone. And Toyota makes more than one type of fake feeler, each with different properties to correspond with gender and age. One dummy might replicate the average male finger, while another may be closer to that of a woman or senior citizen.

Toyota Toyota

The dummy fingers have allowed Toyota to increase safety on the assembly line, but have also factored into the design of new models: the pig skin fingers were used to make safer tonneau covers, which present pinch points where the luggage compartment meets the passenger space.

And the fingers are also useful for improving the safety of car owners by enabling Toyota to study painful accidents drivers may be subject to, such as getting a finger caught in a door jamb. Ouch. As someone who once got their thumb wedged between a car door and the door latch striker, I’ll be the first to admit that I wish I could’ve had a fake finger take the hit for me.

Toyota

Got a tip? Send us a note: tips@thedrive.com